Casing Centralizer

Building on a Legacy of Excellence

Our History

Crimson Oil Tools is a well-known brand in the oil and gas sector for its filling and casing solutions. Years of creativity and talent that have laid a firm basis help to explain this. Our modern facility and staff of highly experienced engineers and workers enable us to routinely produce equipment meeting the highest worldwide requirements.

Crimson Oil Tools : A legacy of innovation, a future of possibilities.

Our commitment to quality, reliability, and innovation has characterised our path. With the help of cutting-edge technologies and strict quality control processes, we've made and sent millions of high-quality tools to customers all over the world, such as case centralisers, float equipment, and mooring plugs.

Key Features of Crimson Oil Tools Centralizers

-

Precision-Engineered Customization

Crimson Oil Tools offers fully customisable centraliser designs, tailored to meet the unique requirements of every well. Whether adjusting dimensions or optimising starting, running, and restoring forces, our solutions are engineered for precision and flexibility. With in-house design capabilities and advanced simulation software, we ensure every product is optimised for peak performance.

-

Advanced Quality Testing Beyond Standards

Our commitment to excellence drives us to test every product beyond API 10D standards. Employing advanced simulation techniques, finite element analysis, and rigorous field testing, we guarantee reliability and durability under the most demanding conditions. Every centralizer undergoes comprehensive quality checks to meet international standards and exceed customer expectations.

-

100% Traceability for Maximum Accountability

Every part of our manufacturing process, from the raw materials to the produced goods, is carefully tracked to make sure that everything can be found. We promise to always give our clients the best goods, and this method of responsibility helps us keep that promise.

-

Optimal Performance with Consistency

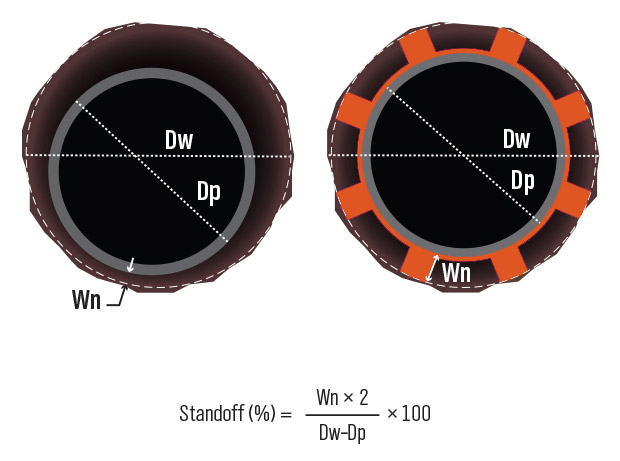

Engineered for consistent performance, Crimson centralisers deliver predictable results in diverse wellbore environments. Our advanced designs optimise standoff, reduce drag forces, and improve cementing efficiency, ensuring the highest level of operational reliability during every run.

-

Superior Bow Strength for Challenging Conditions

Crafted using high-grade alloy steel and precision shaping, our centralizers feature enhanced bow strength and rigidity. These durable designs withstand demanding run-in conditions and minimise the risk of damage when navigating tight restrictions or challenging well geometries.

-

Seamless Mass Production with Repeatable Precision

Our state-of-the-art manufacturing facility ensures each centraliser is produced with consistent quality from the first unit to the last. Utilising advanced CNC machines, automated processes, and stringent quality control measures, we deliver repeatable precision and reliability for every product.

-

Eco-Conscious and Durable Finishing Options

Every centraliser is finished using eco-friendly and durable coatings, including advanced phosphate and powder coatings. These finishes enhance corrosion resistance, improve wear performance, and ensure long-lasting functionality even in harsh environments.