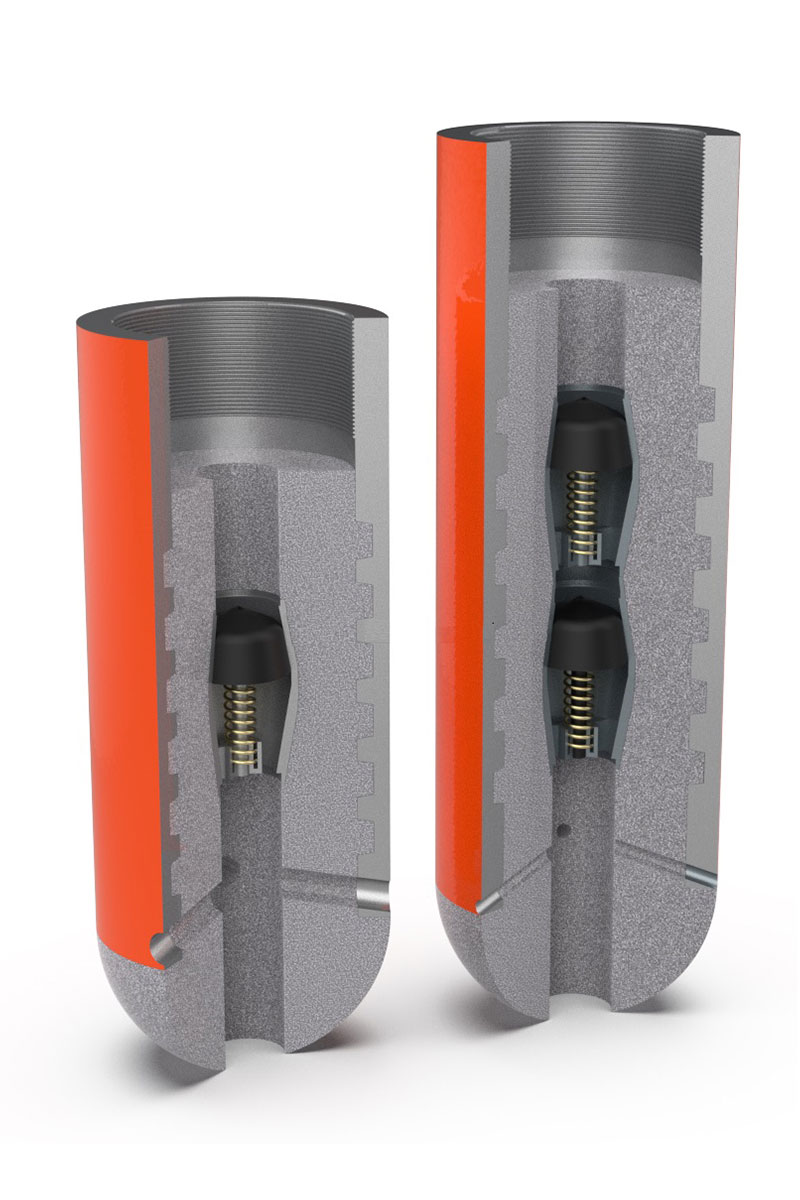

A secure well starts with a strong foundation. Engineers choose cementing plugs to hold structures firmly. These plugs create a barrier that stops leaks. We trust cementing plugs manufacturer in India for quality products. Simple designs and precise engineering build solid wells. Companies invest time and money in durable solutions. Plugs fit snugly between the casing and cement. They secure the well and prevent environmental issues. Strong materials and expert installation yield lasting safety. Owners enjoy peace of mind when they choose these plugs. Well operators trust proven methods to build secure wells. Innovation drives the industry forward each day.

Understanding the Role of Cementing Plugs

Engineers rely on cementing plugs manufacturer in India to provide strong support. Plugs join the casing and cement to stop fluid movement. Designers craft each plug with precision and care. Companies use advanced techniques to mould robust plugs. Laborers put plugs during the process of sealing well parts together securely. A testing phase precedes the final use of plugs. Expert personnel create projects which fulfill safety requirements. The engineering process includes performance measurements with fast plan modifications.

The quality assessment stands vital throughout all plug and cement bond applications. Modern well design increases operational stability along with performance effectiveness. Field teams measure pressure and monitor performance continuously. Engineers share ideas and implement improvements each day. Plugs secure wells with reliable connections and strong materials. Systems work better when every element performs well. Developers review data and adjust techniques for optimal results.

Innovative Benefits and Applications

Operators observe improvements in well’s performance through careful design. Teams monitor pressure, flow, and structural stability constantly. Field experts adjust operations and use efficient methods. Managers plan routines that improve performance steadily. Engineers check data and validate designs during tests. Well’s performance increases when teams work in sync. Operators record results and compare them with benchmarks. Data shows clear benefits of proper installation. Projects save time and resources with each advancement. Success motivates teams to pursue further enhancements. Engineers study feedback and make necessary improvements. Field tests prove the durability of every design. Teams adjust settings and optimize performance in real-time. Operators value innovation and cost efficiency alike. Field experts share insights and lead change. Projects achieve excellence with every careful measure. Engineers commit to quality and lasting performance. Operators report success in every field operation. We finish by choosing a cementing plugs manufacturer in India. Quality always drives progress.

Final Thoughts on Secure Wells

Solid plugs build reliable wells and protect environments. Owners and engineers choose quality over quick fixes. Every decision counts in the success of drilling projects. Investors seek strong foundations that last long. Reliable plugs and strong cement create lasting safety. Smart teams build wells that protect communities. Safety drives progress. Innovation wins always.