Downhole equipment reliability serves as the single factor which determines operational success in the oil and gas sector. The wellbore integrity depends heavily on cementing plugs which serve as one of the essential elements that promote both reliable wellbore stability and effective zonal isolation. Prudent customers seeking reliable cementing plug manufacturers in India should base their choice on criteria beyond mere costs of products. The choice of manufacturing partner determines the performance outcome and compliance level and quality of results for your project. The following research studies essential features which define top cementing plug manufacturers within the competitive Indian market structure.

Manufacturing Excellence and Precision

A leading Indian cementing plug manufacturer maintains constant commitment to manufacturing top-quality products. Modern facilities equipped with precise equipment enable the production of components with exact measurements at the beginning of the process. The manufacturing process needs to perform detailed quality inspections during every phase to maintain batch consistency.

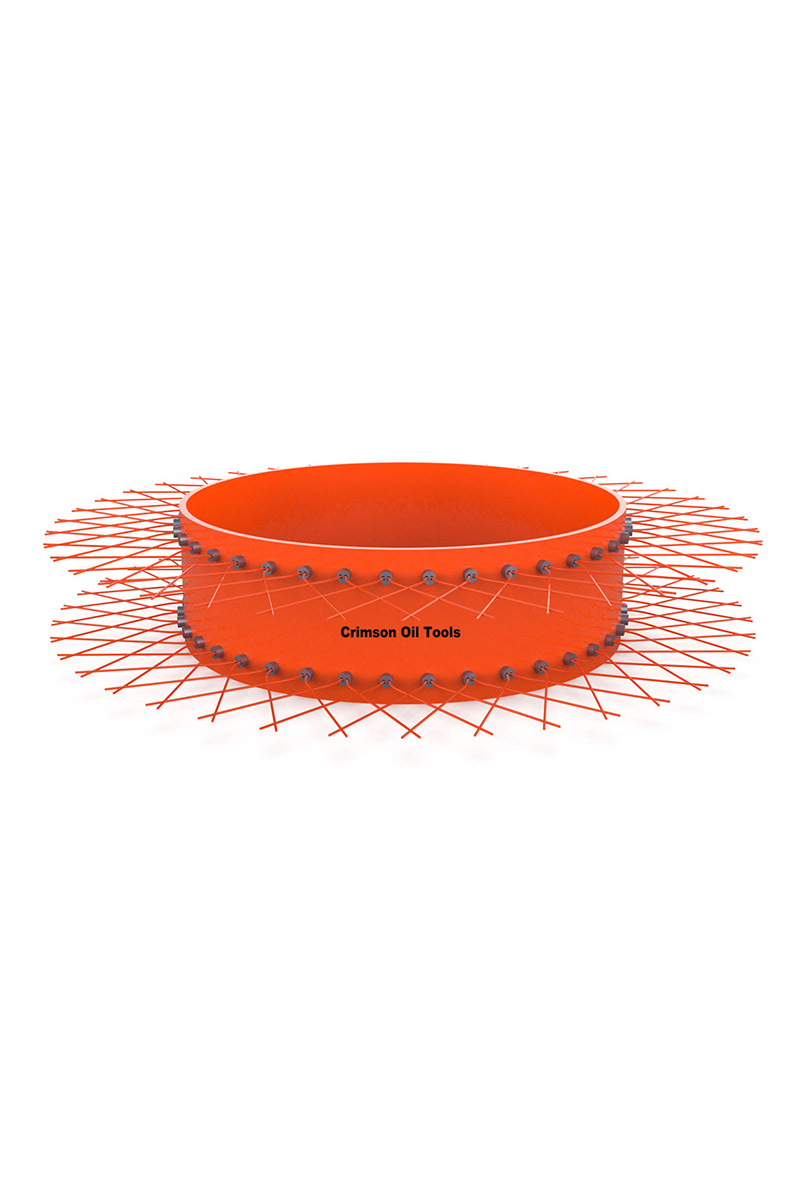

Through CAD/CAM and other leading-edge production methods top manufacturers achieve exact dimensional precision when making their plugs. Companies need this level of accuracy since it ensures safe cementing operations by preventing severe problems that lead to costly repairs and compromised well integrity.

To achieve outstanding manufacturing one must select appropriate raw materials. The extreme lower-hole environment requires high-end producers to use specially designed premium elastomers and composites that withstand the combination of high pressure and temperature along with chemical exposure.

Quality Control and Certification Standards

The assurance of quality through manufacturing precision represents only one part of complete quality management. The leading cementing plug manufacturers in India operate with established quality management systems which adhere to standards from API along with ISO 9001:2015. Transnational quality delivery and continuous improvement procedures are shown through the attainment of these certifications.

Capital testing systems differentiate exceptional manufacturers from unexceptional ones. The complete series of testing encompasses both material compatibility assessments as well as stress evaluation followed by simulated downhole environment testing. Documentation about the testing then provides assurance that products function reliably according to real-world operating conditions.

Customer Support and Technical Expertise

Business dealings between the company and its Indian cementing plug manufacturer should extend beyond their conventional scope. Superior manufacturers act as technical partners to deliver complete assistance starting from product selection through deployment and future services.

Specific well conditions demand precise knowledge about what cementing plug will perform the best. Technical experts work for elite producers to provide personalized advice about cementing processes by using information about well parameters along with cement compounds and operational objectives.

After-sales support from premier manufacturers proves to be the most notable feature of their services. The company provides extended support through field service teams while also maintaining assistance with trouble diagnosis and technical expertise when technical help is necessary. A manufacturer proves their commitment to customer satisfaction through immediate response to customer issues and delivering problem solutions.

Conclusion

Manufacturers offering cementing plug solutions should be selected through careful examination of facilities that enable customer support and quality control measures and manufacturing function. High-quality manufacturers merge their enthusiastic commitment to achieving excellent results and satisfied customers with superior technical capabilities. Operational success along with enhanced well integrity can be achieved through collaboration with a leading Indian cementing plug manufacturer which also helps reduce non-productive time. Cementing manufacturers who evolve their products through innovation according to market needs will become the key partners for worldwide demanding cementing services.