Being a float collared manufacturer in India, we are aware of the difficult terrain of oil well operations across the various geological settings of the subcontinent. Whether you are negotiating the difficult formations in Gujarat or controlling wells in the sweltering Rajasthan, good well integrity is still absolutely vital for effective drilling operations.

Understanding Float Equipment Fundamentals

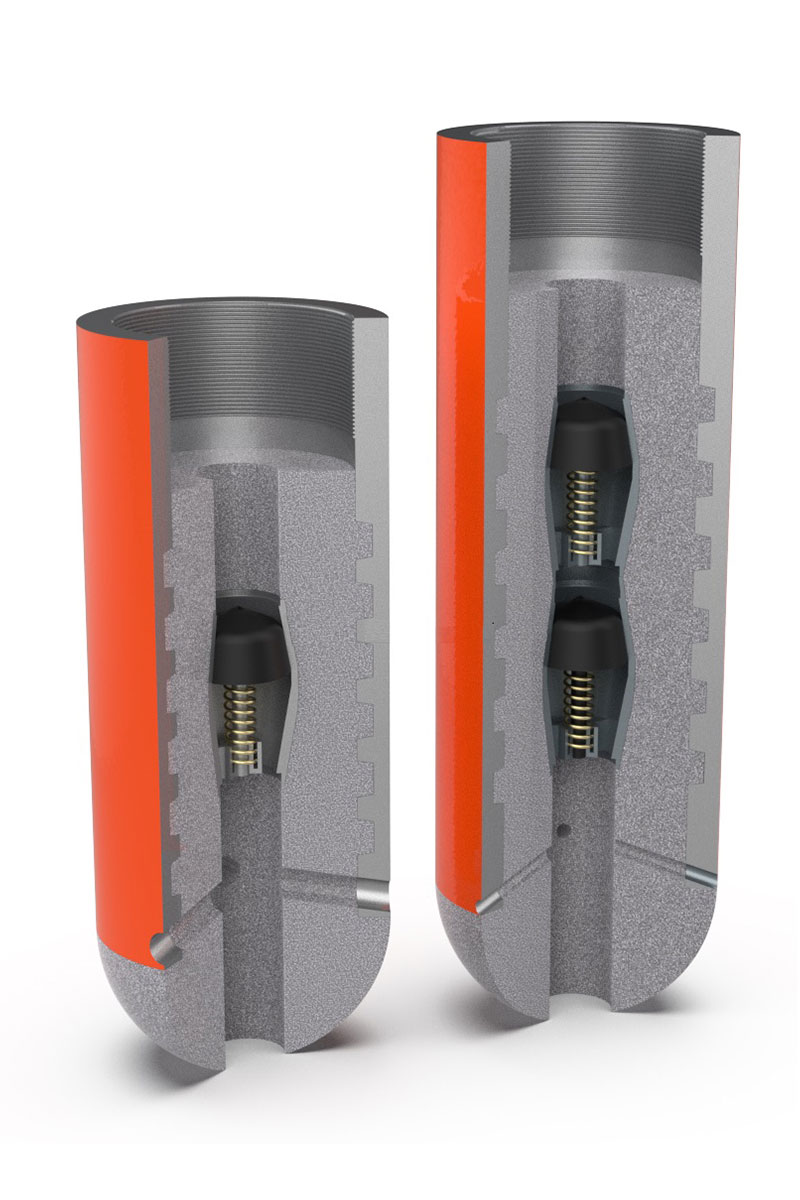

The foundation of successful well drilling operations lies in mastering float equipment basics. In India’s varied geological conditions, from the Krishna Godavari basin to the Mumbai High fields, proper float equipment selection plays a vital role in maintaining well control and ensuring drilling efficiency.

- Material engineering focuses on developing corrosion-resistant components suited for high temperature and pressure environments common in Indian oil fields

- Design innovation shapes equipment functionality through computational fluid dynamics and structural analysis

- Quality assurance encompasses rigorous testing protocols aligned with international standards and Indian regulatory requirements

Advanced Float Equipment Technologies

Modern drilling operations demand sophisticated solutions. As a leading float collar manufacturer in India, we witness the continuous evolution of technology adapting to complex drilling environments.

- Smart sensors enable real-time monitoring of float equipment performance during critical drilling phases

- Automated systems enhance operational efficiency through precise control of drilling parameters

- Digital integration allows seamless data collection and analysis for optimized equipment performance

- Enhanced materials provide superior wear resistance in challenging well conditions

Performance Optimization Strategies

Every oil well presents unique challenges requiring tailored solutions. The expertise of a float collar manufacturer in India becomes invaluable when optimizing equipment performance across different geological settings.

- Customization options allow equipment adaptation to specific well conditions and operational requirements

- Performance monitoring systems track equipment efficiency throughout the drilling process

- Maintenance protocols ensure consistent equipment reliability and longevity

- Technical support provides expert guidance during equipment selection and installation

Regional Considerations and Applications

In the diverse Indian oil fields, equipment requirements vary significantly. Working with a reliable float collar manufacturer in India ensures access to solutions tailored for local conditions.

- Geological factors influence equipment selection based on formation characteristics

- Environmental conditions impact material choices and equipment specifications

- Regulatory compliance guides equipment design and implementation strategies

- Local expertise contributes to effective equipment deployment and operation

- Supply chain integration ensures timely equipment availability and support

Future Trends and Developments

The oil and gas industry continues to advance, with float collar manufacturers in India leading innovation in float equipment technology. These developments shape the future of well drilling operations.

- Research initiatives drive continuous improvement in equipment design and functionality

- Sustainability focus promotes environmentally conscious equipment solutions

- Technology integration enhances equipment performance through digital innovations

- Market expansion creates opportunities for advanced equipment applications

- Industry collaboration fosters knowledge sharing and technical advancement

Conclusion

Advanced float equipment technology represents a cornerstone of modern well drilling operations. Understanding its applications, considering regional factors, and staying informed about technological developments empowers drilling teams to achieve optimal results.

Leave a Reply