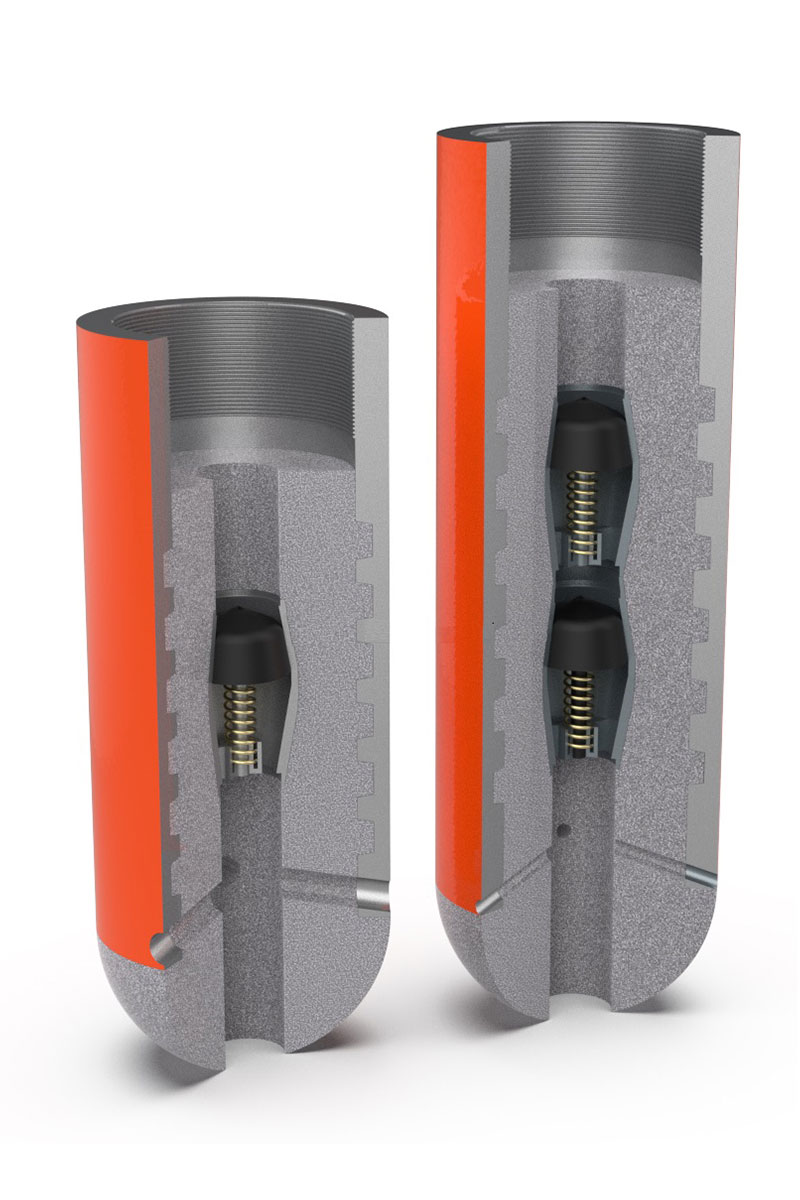

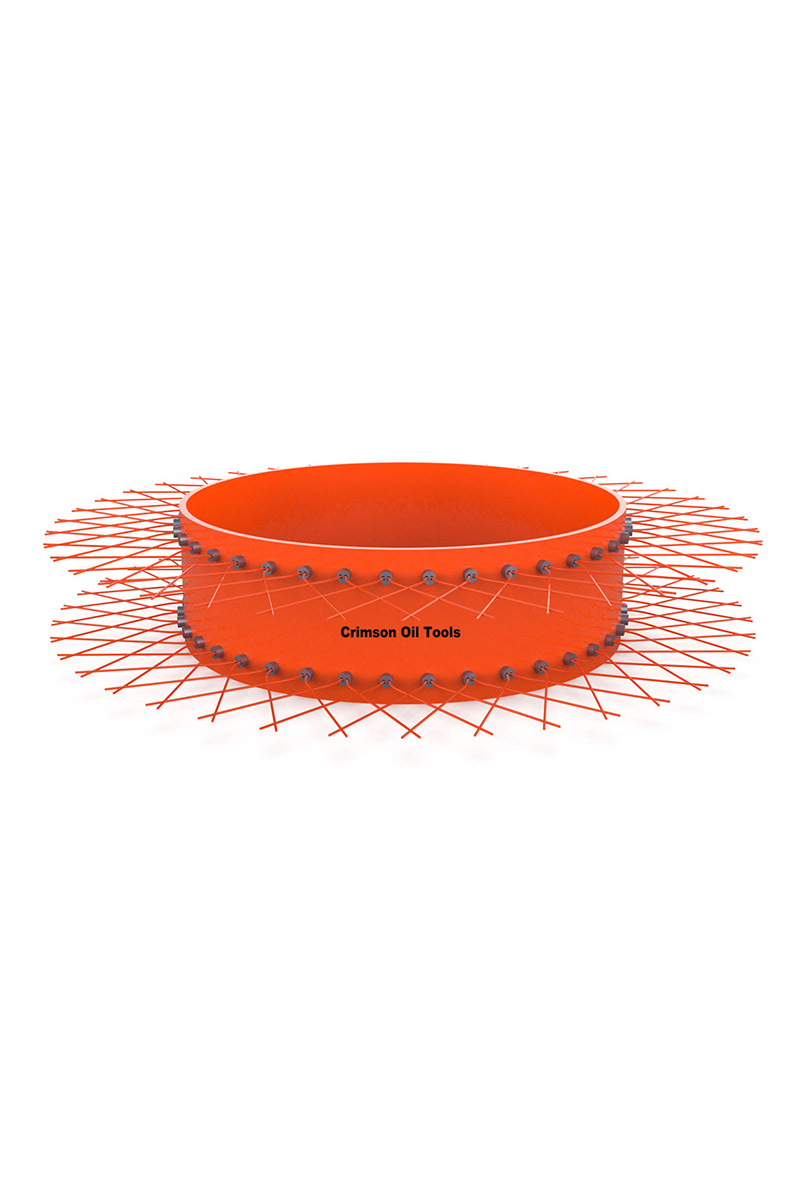

The selection of an appropriate equipment manufacturer for the oil and gas sector establishes both operational effectiveness and project security as well as achievement of the required end results. Float collars act as indispensable elements in casing running and cementing operations since they block cement backflow and maintain correct cement displacement. The selection process for a float collar manufacturer in India should contain a few essential aspects which could ensure you find a provider that delivers what you need and produces reliable quality products.

Technical Expertise and Manufacturing Capability

The search for an Indian float collar manufacturer should balance their expertise in materials and manufacturing capabilities. Your choice should be a partner who invents and builds float collars that suit various well environments and multiple operational needs. When working as a reputable manufacturer the company needs to show complete understanding of ruling rules and top field practices.

Users have to inspect both the facilities and manufacturing tools and quality assurance practices. The company produces high-quality items by using modern CNC machines plus precise tools together with high-tech testing equipment. Your research should establish how the supplier’s production speeds and manufacturing capability match your order needs for top-tier products.

There are many qualified engineers and technicians working for the best float collar manufacturer in India. The team understands the complex nature of downhole operations to create products that function effectively in such conditions. Technical knowledge of the staff enables them to discuss specifications for technical features as well as provide engineering support when requested.

Quality Standards and Certifications

The selection of downhole tools requires absolute commitment to high-quality standards. Float collars of poor quality have the potential to damage the casing and cement while leading to well failure. For a float collar manufacturer in India to be reliable, they should follow strict quality control measures at all times.

Look for certifications that include ISO 9001 and API Spec Q1 together with product-specific API 10F certifications. The certifications confirm that the company implements standardised quality management systems and worldwide recognised product standards. Request documentation that proves their quality testing procedures alongside methods which ensure consistent product output across all their production runs.

Customer Service and Flexibility

The quality of customer service matches technical abilities and manufacturing standards for successful teamwork in product development. Manufacturers that excel at fulfilling individual requirements need to both follow your directions and immediately detect your requirements.

Verify their willingness to create solutions that match your well conditions. A quality float collar manufacturer collaborates with customers to understand their requirements before proposing design modifications to fulfil their needs.

Conclusion

The selection of a suitable Indian float collar manufacturer enables you to operate your drilling operations with improved safety as well as operational efficiency together with cost reduction and compliance with project-specific and standard regulations.