Have you ever attempted to install a stop collar in a wellbore that required passing through Mumbai traffic during rush hour? Those who have experienced tight access situations already know traditional stop collars are not suitable, but hinged stop collars could become your ideal downhole solution.

The following discussion explains how hinged stop collars function as the preferred tool for professionals working with challenging completion systems and demanding time constraints. Read on to find out why more engineers are turning to these mighty little components — and how to choose the right stop collars manufacturer in India to get the job done right.

What’s a Hinged Stop Collar, Anyway?

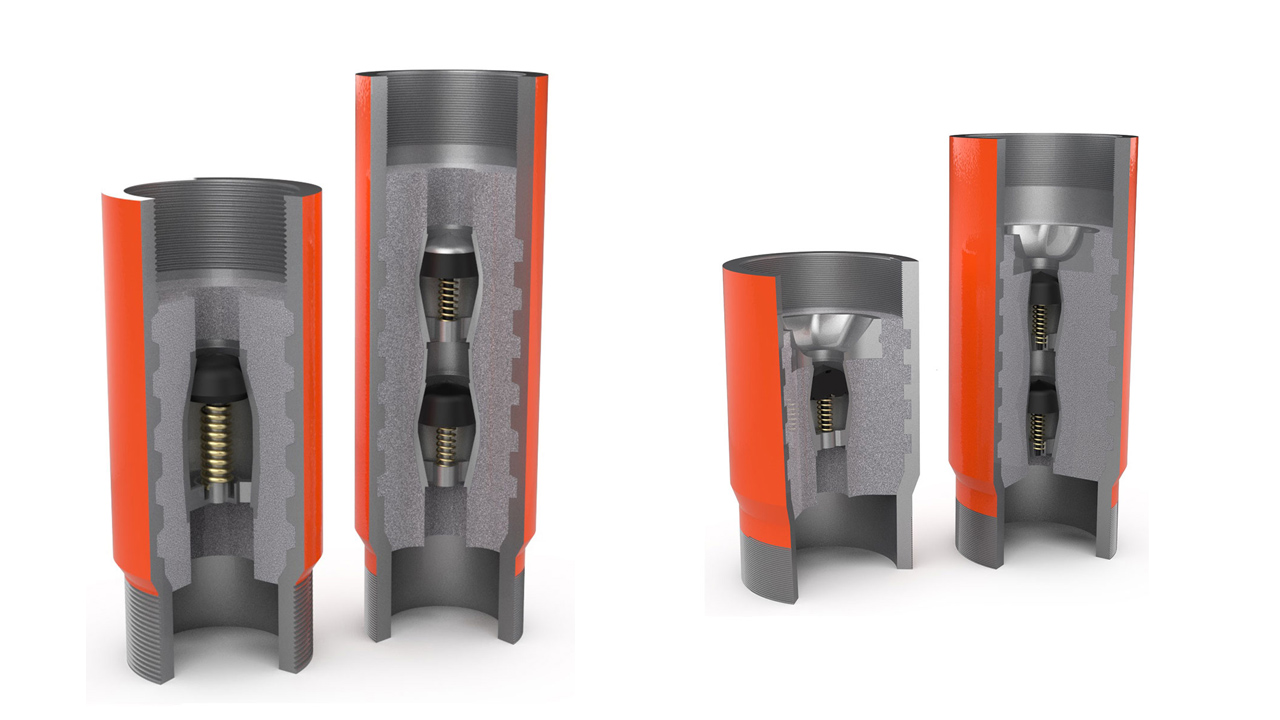

A stop collar is a mechanical device that prevents centralizers or other downhole tools from sliding along the casing. Simple? Sure. But critical? Absolutely.

There are three primary types:

● Set screw collars (secured with screws into the casing)

● Friction collars (rely on tight fit and surface contact)

● Hinged stop collars (split design that wraps around casing, secured by latch, bolts, or lock pins)

Why Hinged Stop Collars Outperform in Tight Access Jobs

Let’s face it — nobody wants to wrestle with a collar in 45°C heat while fighting a deadline. Hinged designs offer unique benefits that simplify installation, boost reliability, and reduce NPT (non-productive time).

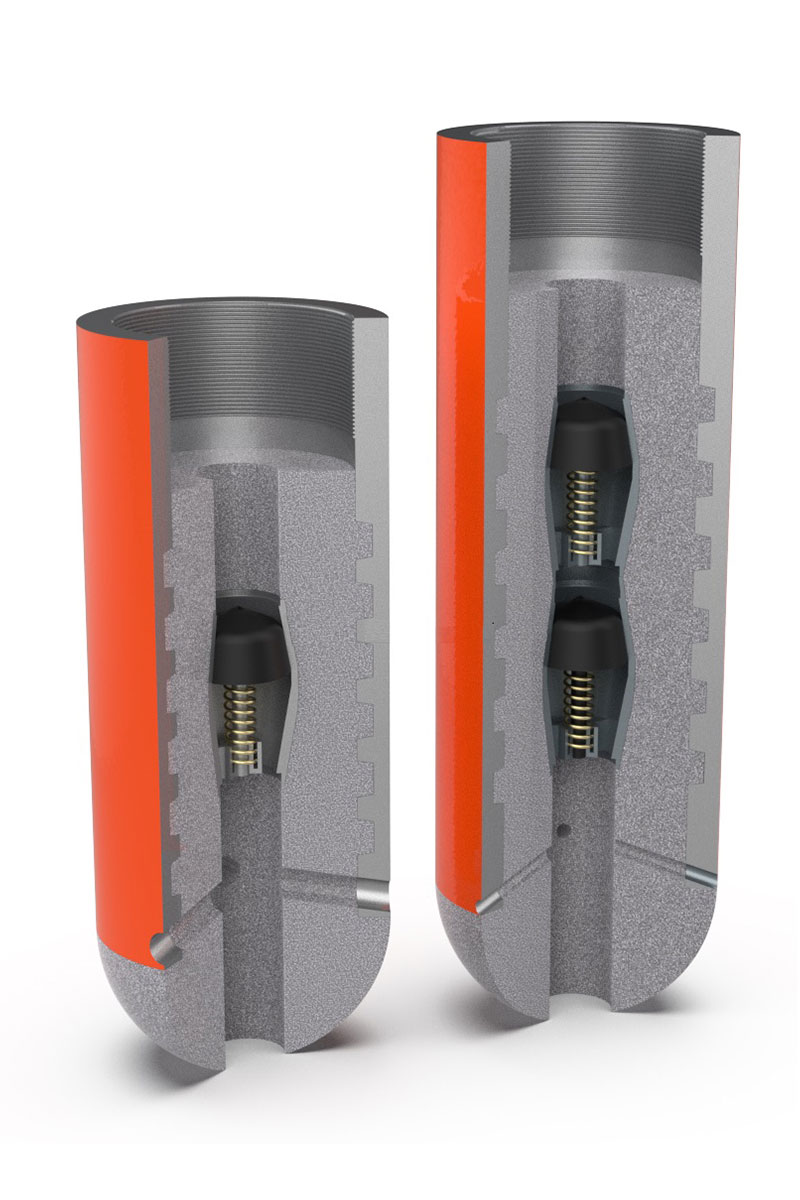

Tool-Free, Hassle-Free Installation

Unlike set screw models that require torque wrenches or friction types that need perfect alignment, hinged stop collars can be installed by hand and tightened with minimal tools. That’s a big win when:

● Your rig floor is cramped

● Time is tight

● You’re working at odd angles

Strong Hold Without Damage

Indian manufacturers of hinged collars develop precise products that securely hold well casings while safeguarding the casing structure for sensitive operations and regulatory purposes.

High Torque Resistance

Modern hinged collars are designed for high-torque wells and lateral movements. Field tests have shown that some models outperform traditional collars under simulated directional drilling conditions.

Field Insight:

An onshore crew in Rajasthan reported 22% faster install times and zero collar slippage during a 6,000 ft run after switching to hinged models from a stab in stinger supplier in India that also manufactures stop collars. That’s measurable efficiency — and fewer headaches for the field team.

Conclusion

en Space Is Tight, Don’t SettleHigh-stakes locations such as deepwater wells and tight land rigs do not allow any form of slippage, whether physical or metaphorical. Hinged stop collars provide businesses with a strong and fast solution that requires minimal effort to operate. Companies seeking both operational continuity and straightforward systems should choose stop collars.

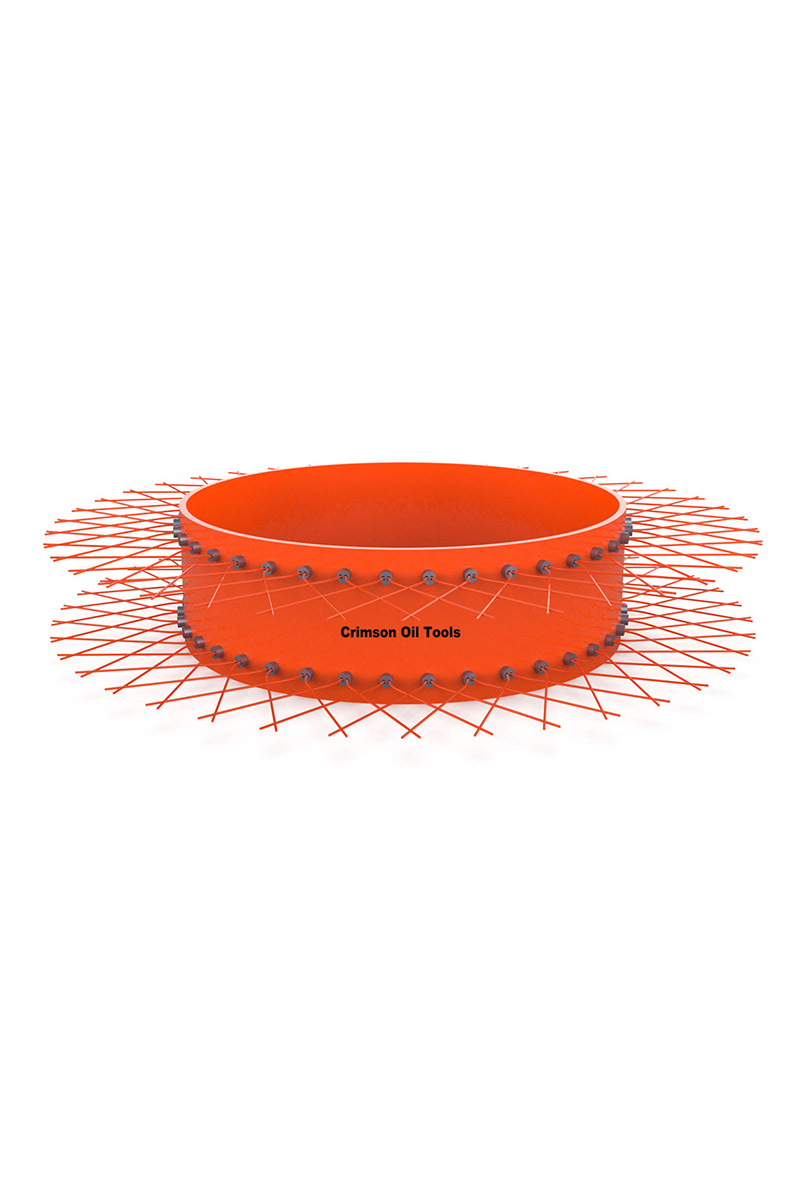

Stay informed, Stay ahead and Stay inspired with Crimson Oil Tools